The oil and gas industry faces complex challenges related to risks that can impact safety, the environment, and financial performance. This article examines how generative artificial intelligence (AI), a cutting-edge technology that can generate scenarios, predictions, and solutions from data, is revolutionizing risk management in this sector. We focus on the early identification of risks, such as equipment failures or environmental incidents, and the development of effective risk treatment plans. Using accessible language, the article explains what generative AI is, how it works, and its practical applications in the oil and gas industry. A detailed case study illustrates how this technology can be used on an offshore platform to prevent accidents and optimize risk responses. Additionally, we discuss the benefits, including increased accuracy and cost reduction, as well as the challenges, such as the need for high-quality data and training. This article highlights the transformative potential of generative AI, suggesting paths to a safer and more efficient future in the industry.

1. Introduction

The oil and gas industry is crucial to the global economy, supplying energy to millions of people and businesses. However, operating in this sector is like walking through a minefield: risks are everywhere. From explosions on offshore platforms to oil spills that harm the environment, the dangers are real, and the consequences can be devastating. Managing these risks is a critical yet incredibly complex task due to the multitude of variables involved, including weather conditions, mechanical failures, and human errors.

Traditionally, risk management relies on experts who analyze data, make predictions, and create plans to avoid problems. However, this process is time-consuming, costly, and sometimes limited by the human capacity to process vast amounts of information. This is where generative artificial intelligence comes in, a technology that is revolutionizing how companies identify and address risks. Generative AI not only analyzes data but also creates scenarios, suggests solutions, and predicts issues before they occur, all with remarkable speed and accuracy.

The purpose of this article is to explain, in a clear and accessible manner, how generative AI can transform risk management in the oil and gas industry, with a focus on risk identification and the development of treatment plans. We will explore what this technology is, the challenges in the sector, how AI can help, and the benefits and limitations of its application. To illustrate, we present a fictional yet realistic case study that demonstrates how generative AI can be utilized on an offshore platform to prevent accidents and optimize operations. If you’ve ever wondered how technology can make the world safer, this article is for you.

2. What is Generative AI?

Before exploring how generative AI supports risk management, let’s first understand what it is. Imagine a supercomputer that not only analyzes information but also thinks creatively, like a writer or strategist. Generative AI is a category of artificial intelligence that can create new things, such as texts, images, predictions, or simulations, based on the data it has been trained on.

For example, if you show a generative AI thousands of reports about equipment failures in a refinery, it can learn patterns and create a realistic but fictional report about how a failure might occur in the future. Or, if you provide data on oil spills, it can simulate scenarios of how a spill might happen and suggest ways to prevent it. This ability to “create” is what makes generative AI so powerful.

How does it work? In simple terms, generative AI is trained with large amounts of data, such as reports, equipment images, or weather records. It uses this data to understand patterns and relationships, such as the likelihood of a component failing under specific conditions. Then, it can generate predictions, simulations, or even action suggestions. Think of it as a super-intelligent assistant that not only finds answers but also proposes new ideas.

In the oil and gas industry, where data is abundant and complex, generative AI is particularly useful. It can analyze sensor data, maintenance reports, weather conditions, and even global news to identify risks that humans might overlook. Let’s now explore why risk management is so critical in this sector.

3. Risk Management in the Oil and Gas Industry

Risk management involves identifying, assessing, and controlling potential problems before they cause harm. In the oil and gas industry, this is crucial because the risks are numerous and can have severe consequences. Let’s take a look at the main types of risks companies face:

- Operational risks: These include equipment failures, such as pumps or valves, which can halt production or cause accidents like explosions or fires.

- Environmental risks: Oil or gas leaks can pollute oceans, rivers, and soil, causing environmental damage and hefty fines for companies.

- Financial risks: Production interruptions or accidents can cost millions of dollars, not to mention damage to the company’s reputation.

- Safety risks: Human errors or safety failures can lead to accidents that endanger workers’ lives.

- Regulatory risks: Changes in environmental or safety laws can require costly adjustments to operations.

Identifying these risks is not easy. Picture an offshore platform in the middle of the ocean, with thousands of equipment components, sensors generating data every second, and teams working around the clock. Engineers must analyze this data, predict potential problems, and determine the best course of action, all under pressure. Additionally, traditional methods rely heavily on human expertise, which, while valuable, may not be sufficient to quickly process large amounts of information or predict rare events.

Addressing these risks is also challenging. A risk treatment plan may include actions such as repairing equipment, training teams, or installing barriers to prevent leaks. But how do you decide which action is most important? Or how do you predict whether a plan will work? This is where generative AI can make a difference, as we’ll see in the following sections.

4. How Generative AI Helps in Risk Identification

Generative AI is like a tireless detective that analyzes clues and predicts crimes before they happen. In the oil and gas industry, it can identify risks faster and more accurately than traditional methods. Let’s see how this works with some practical examples:

- Historical data analysis: Imagine a company has thousands of reports on valve failures in a refinery. Generative AI can analyze these reports and identify patterns, such as “valves of a certain type fail more often at temperatures above 40°C.” With this, it can alert engineers about which valves need maintenance before they break.

- Environmental risk prediction: Generative AI can use sensor data and weather forecasts to predict the likelihood of an oil spill. For instance, if it detects that strong winds are forecast for an area with an aging pipeline, it can warn about the risk of rupture.

- Scenario simulation: AI can create “what-if” simulations. For example, “What if a pump fails during a storm?” It can generate realistic scenarios showing how the issue could affect the platform and its consequences, helping teams prepare.

- Anomaly detection: Sensors on offshore platforms generate millions of data points daily. Generative AI can analyze this data in real-time and identify anomalies, such as unusual pressure in a tank, which could indicate an imminent problem.

For example, on an offshore platform, generative AI could analyze sensor data from a pipeline and notice that small vibrations, combined with the pipeline’s age, increase the risk of cracks. It would then alert the team, suggesting an immediate inspection. This ability to predict problems before they occur is a game-changer in risk management.

5. Risk Treatment Plans with Generative AI

Identifying risks is only half the battle; the next step is deciding what to do about them. Generative AI also excels in developing risk treatment plans, suggesting practical actions and optimizing strategies. Let’s explore how this works:

- Mitigation action suggestions: AI can propose specific solutions for each identified risk. For example, if it detects a risk of pump failure, it might suggest replacing a part, adjusting maintenance, or changing the operations schedule to reduce stress on the equipment.

- Action prioritization: Not all risks are of equal severity. Generative AI can rank risks based on their likelihood and impact, helping teams focus on what’s most urgent. For instance, it might determine that repairing a valve is more critical than training a team because the valve is more likely to cause an accident.

- Outcome simulation: Before implementing a plan, AI can simulate what would happen if it were put into action. For example, if the company decides to reinforce a pipeline, AI can predict how this would reduce the risk of a leak and estimate the cost, enabling better decision-making.

- Resource optimization: AI can suggest ways to utilize the company’s resources (such as budget, time, and personnel) more efficiently. For example, it might recommend performing maintenance on multiple pieces of equipment simultaneously to reduce costs.

Imagine a refinery that identified a risk of a leak in a tank. Generative AI could suggest three options: reinforce the tank, replace it, or monitor it with additional sensors. It could also simulate the costs and benefits of each option, helping the company choose the best strategy. This approach not only saves time but also ensures decisions are based on solid data.

6. Case Study: Preventing Accidents on an Offshore Platform with Generative AI

To illustrate the power of generative AI, let’s consider a fictional but realistic scenario at the Starfish Platform, an offshore oil extraction facility located in the Atlantic Ocean, 200 km off the coast. The platform operates in deep waters, facing harsh conditions like frequent storms, high equipment pressure, and a corrosive environment due to seawater salinity. Below, we detail the context, problem, application of generative AI, tools used, results, and two tables organizing the identified risks and simulated scenarios.

Context: The Starfish Platform is one of the largest facilities of the fictional PetroMar company, extracting 100,000 barrels of oil per day. The platform has thousands of sensors monitoring pumps, valves, pipelines, and tanks, generating terabytes of data daily. Despite this, the company struggled to process this data quickly. Past pump failures had caused production halts, minor leaks, and environmental fines. Additionally, a storm was forecast for the next 15 days, heightening the urgency to identify and address risks.

Problem: Maintenance reports indicated abnormal vibrations in several extraction pumps, but the team couldn’t determine which ones were most at risk of failure. There were also concerns about aging pipelines and storage tanks, which could be affected by the storm. Manual data analysis was slow and couldn’t predict rare events, such as multiple equipment failures. The company needed a solution to accurately identify risks and suggest priority actions to prevent accidents, protect the environment, and maintain production.

Solution with Generative AI: PetroMar decided to implement Grok 3, a generative AI tool developed by xAI, to manage the platform’s risks. Grok 3 was chosen for its ability to analyze large datasets and generate predictions and action plans based on complex patterns. The engineering team fed Grok 3 with the following data:

- Historical maintenance reports (10 years of data on pump, valve, and pipeline failures).

- Real-time sensor readings (vibrations, pressure, temperature).

- Weather forecasts (winds up to 80 km/h and 5-meter waves expected).

- Records of environmental and operational incidents.

Prompt Used for Risk Register: To ensure Grok 3 delivered useful results, the team used the following clear and structured prompt:

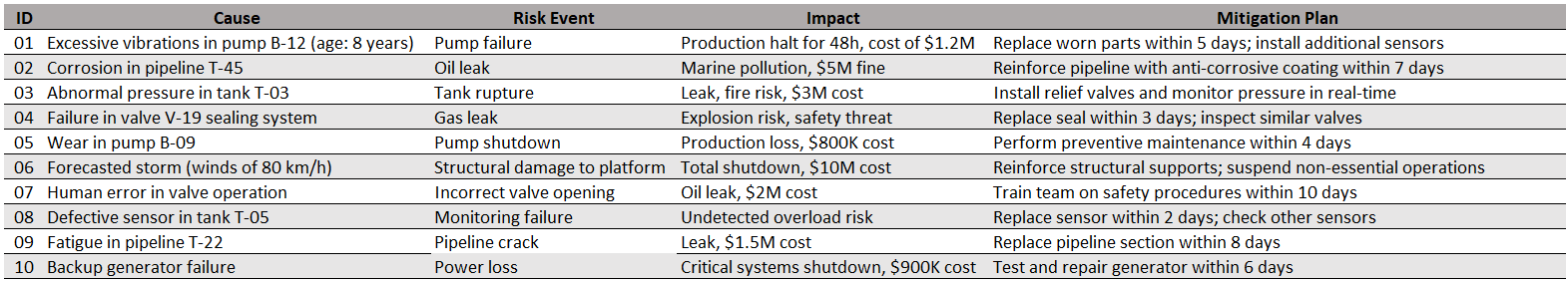

“Analyze the historical maintenance data, real-time sensor readings, and weather forecasts for the Starfish Platform. Identify the top 10 operational and environmental risks most likely to occur in the next 30 days, considering the forecasted storm. For each risk, provide: (1) a description of the cause, (2) the risk event, (3) the potential impact, and (4) a detailed mitigation plan. Prioritize the risks based on likelihood and impact. Generate an organized table with this information and suggest immediate actions to prevent accidents.”

Grok 3 processed the data and generated the following risk register table:

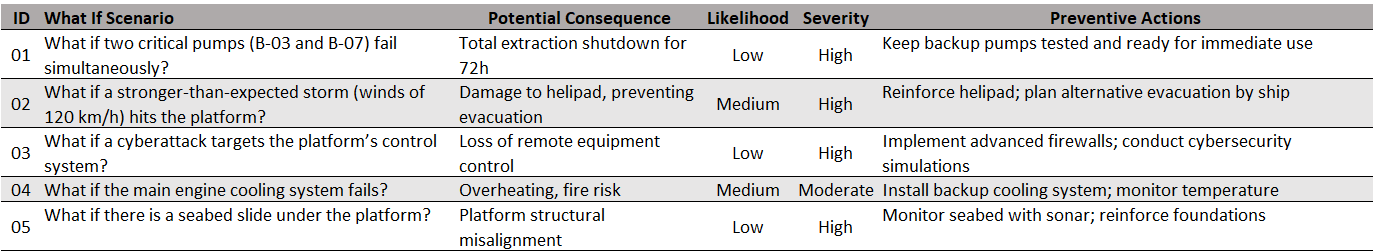

“What If” Analysis with Generative AI: To complement the risk identification, the team used Grok 3 to perform a “What If” analysis, a technique that explores hypothetical scenarios to anticipate potential failures under extreme or unexpected conditions. The goal was to identify additional risks not covered in the initial analysis, which could arise in critical situations. The prompt used was:

“Perform a ‘What If’ analysis for the Starfish Platform, considering extreme and hypothetical scenarios, such as simultaneous equipment failures, weather conditions beyond the forecast, or unforeseen external events. Identify 5 additional risks distinct from those in the risk register table. For each risk, describe: (1) the ‘What If’ scenario, (2) the potential consequence, (3) the likelihood (low, medium, high), (4) the severity (low, moderate, high), and (5) preventive actions. Present the results in a table.”

Grok 3 generated the following table based on the “What If” analysis, using columns specific to the methodology:

Implementation and Results: Based on Grok 3’s analyses, PetroMar prioritized immediate actions from the risk register, including replacing parts in pumps B-12 and B-09, reinforcing pipeline T-45 with an anti-corrosive coating, and installing relief valves in tank T-03. Additionally, the company implemented preventive measures from the “What If” analysis, such as reinforcing the helipad and conducting cybersecurity tests. During the forecasted storm, which occurred with winds of 80 km/h, no significant failures were recorded. Production continued uninterrupted, and the company avoided a potential leak that could have resulted in $5 million in environmental fines and repairs. The “What If” analysis also prepared the team for extreme scenarios, such as a potential cyberattack, enhancing the platform’s resilience.

Case Study Conclusion: The use of Grok 3 on the Starfish Platform demonstrated the transformative power of generative AI in risk management. The risk register table provided a clear and actionable view of immediate hazards, enabling PetroMar to prioritize actions to prevent accidents and maintain production. The “What If” analysis expanded the team’s perspective, identifying hypothetical risks that might have been overlooked, such as simultaneous equipment failures or external events like cyberattacks. Well-structured prompts ensured that Grok 3 delivered accurate and practical results, translating complex data into strategic decisions. As a result, PetroMar not only avoided financial and environmental losses but also strengthened its ability to handle rare and extreme events. This case highlights how generative AI can be a powerful ally in building safer and more efficient operations, and PetroMar plans to expand Grok 3’s use to other platforms, integrating it with real-time monitoring for even more proactive risk management.

7. Benefits and Challenges of Generative AI in Risk Management

Generative AI offers impressive benefits for risk management in the oil and gas industry but also comes with challenges. Let’s examine both sides:

Benefits:

- Greater accuracy: AI can identify risks that humans might miss, analyzing vast amounts of data in real-time.

- Speed: While an engineer might take days to analyze reports, AI does it in minutes.

- Cost reduction: Preventing accidents and optimizing resources saves millions of dollars.

- Better decision-making: Simulations and predictions enable companies to choose the most effective strategies.

- Safety and sustainability: By preventing leaks and accidents, AI protects workers and the environment.

Challenges:

- Data quality: AI needs reliable and complete data to function effectively. Inaccurate data can lead to incorrect predictions.

- Team training: Workers need to learn how to use AI and trust its recommendations, which requires time and investment.

- Initial cost: Implementing AI can be expensive, especially for smaller companies.

- Ethical concerns: There are concerns about data privacy and the responsible use of AI, particularly when it’s used to make decisions that affect workers.

Despite these challenges, the benefits of generative AI outweigh the difficulties, especially in a sector where errors can have catastrophic consequences. Over time, as the technology becomes more accessible and teams adapt, these challenges are likely to diminish.

8. Conclusion

Generative artificial intelligence is transforming the way the oil and gas industry manages risks, delivering enhanced safety, efficiency, and sustainability. As we’ve seen, it can identify risks with precision, predict problems before they occur, and suggest intelligent action plans, all with a speed that traditional methods cannot match. The Starfish Platform case study demonstrated how generative AI, through Grok 3, can prevent accidents, save money, and protect the environment in a practical and accessible manner.

Looking to the future, the potential of generative AI is even greater. As technology evolves, it can integrate further with operations, combining innovations such as advanced sensors and autonomous robots to create even more robust risk management systems. Imagine a future where offshore platforms operate almost without human intervention, with AI monitoring everything in real-time and making decisions to prevent issues before they arise.

For oil and gas companies, adopting generative AI is not just about keeping up with technology but about ensuring a safer and more sustainable future. While challenges like data quality and team training exist, the positive impact of AI is undeniable. This is just the beginning of a revolution that promises to transform the industry, making it better prepared to face the challenges of the 21st century.